MSYH M760 PVC Coil Floor Adhesive

Special glue for pvc coil floor, high-efficiency water-based adhesive, suitable for pasting all kinds of PVC coil floor and sheet floor, carpet with PVC back layer, etc. on the absorbent base.

MSYH M760 PVC Coil Floor Adhesive

M760 is suitable for all kinds of PVC membrane floors, dense and low-foaming bottoms, homogeneous and permeable floors, etc. It is a classic PVC membrane floor glue. Practice has proved that the special glue for M760 membrane has good bonding effect and environmental protection performance. , is widely used in medium and large PVC coil floor projects. High-efficiency water-based adhesive, suitable for sticking various types of PVC coil flooring and sheet flooring, PVC backing carpets, etc. on the absorbent base.

use:

High-efficiency water-based adhesive, suitable for sticking all kinds of PVC coil and sheet floors, carpets with PVC backing, etc. on the absorbent base.

Features:

The initial adhesion is high, and the newly laid floor is not easy to shift;

Can withstand the extrusion of the steering wheel of indoor chairs;

Easy to construct, practical and economical;

Green and environmental protection, in line with GB 18583-2008 standard;

Applicable base layer:

1. Suitable for porous, absorbent, firm, flat, dry, clean, crack-free, grease-free, wax-free floors;

2. Suitable for hard cement-based self-leveling leveling layer;

3. Suitable for raised wood floors, plywood and particleboard.

Basic treatment:

If the base layer has oil stains, wax water and release agent, etc., it needs to be decontaminated with waxing water; it is recommended to use M318 water-based interface agent to seal and reinforce the slightly sandy ground; Carry out construction leveling (leveling thickness at least 2mm); it is recommended to use a two-component epoxy moisture-proof interface agent for moisture-proof treatment on the wet base. The base layer with cracks is recommended to be repaired with a two-component epoxy material.

technical parameter:

Color: milky white

PH value: 7-8

Density: 1.4kg/L

Dosage: 250-350g/㎡

Waiting time: about 10 minutes (varies with humidity and temperature)

Bearing time ≥ 24h

Final setting time≥72h

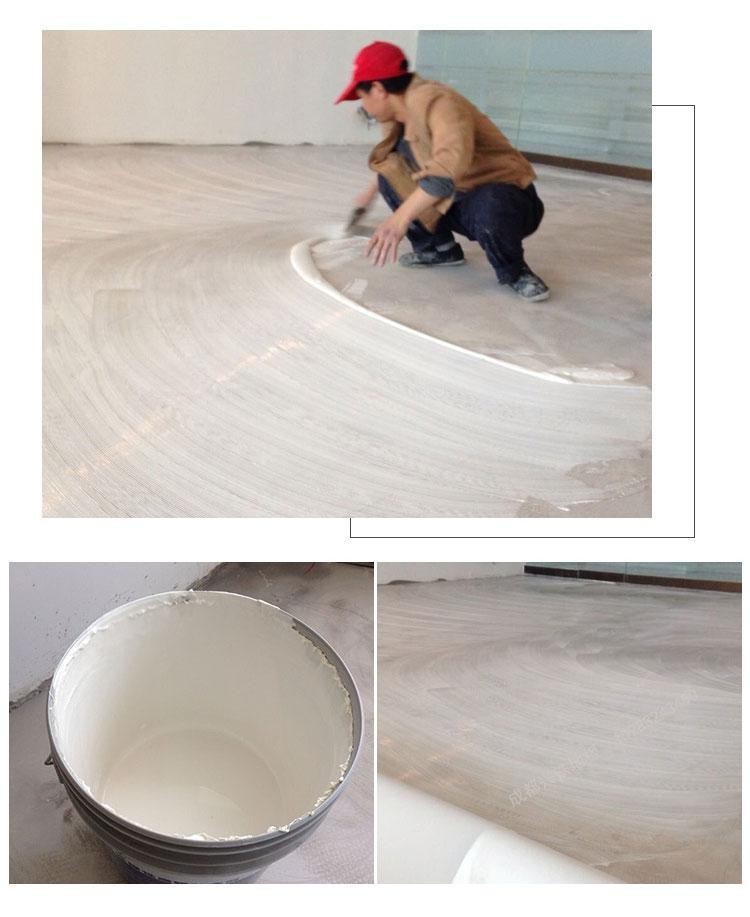

Construction method:

Without dilution, use A2 toothed squeegee to apply the adhesive evenly on the surface of the base. If a small amount of clear liquid is found on the surface after opening the barrel, the adhesive needs to be stirred evenly before construction. According to the temperature and humidity of the construction site, wait for about 10 to 20 minutes (there is a noticeable brushing feeling when you touch the hand), and then you can lay the floor. Use the cork exhaust to push the floor flat, and then use a 50 kg roller on the paved floor. Rolling on top can achieve better results.

Precautions:

If the construction environment temperature is lower than 15℃ and the relative humidity is higher than 75%, please consult our technical staff. If there is a film on the surface of the adhesive after opening, it needs to be removed first, and it can be used after stirring evenly. Do not pour the adhesive into the gutter or sewers. After the construction is completed, the lid of the bucket that has not used up the adhesive should be sealed and stored. Tools can be cleaned with water.

Packaging and Storage:

25kg plastic drum packaging. This product must be stored indoors at 5°C to 35°C to prevent freezing and exposure. Shelf life is 12 months.

Quote online

Navigator

Contact Hedsom

Contact:Winsom

Mobile:+8618664748006

Email:export@hedsom.com

Comanpy:Hesom SPC flooring

Address:No. 555, Huangpu Avenue East, Tianhe District, Guangzhou, China