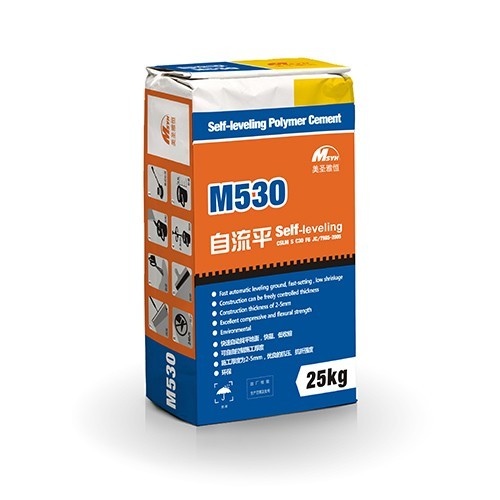

MSYH M530 High-strength cement self-leveling

It is made of special cement, fine aggregate, foreign brand polymer spray dry powder resin and other cement additives and other raw materials.

MSYH M530 High-strength cement self-leveling

It is made of special cement, fine aggregate, foreign brand polymer spray dry powder resin and other cement additives and other raw materials.

use:

M530 high-strength self-leveling is made of special cement, fine aggregate and foreign brand polymer spray dry powder resin and other cement additives. It is a self-leveling foundation material with high fluidity and high plasticity, suitable for heavy commercial buildings. , industrial and other occasions.

Features:

Quickly and automatically level the ground, fast setting and low shrinkage; the construction thickness can be freely controlled; the construction thickness is 2-5mm, excellent compressive and flexural strength; environmental protection.

Applicable base:

It is suitable for all kinds of floors, carpets, ceramic tiles, floor tiles and other ground materials, providing them with a flat, intact and solid ideal base layer. It is a non-toxic and harmless green product.

Basic treatment:

The base layer must be dry, firm, load-bearing, free from dust, free from debris that hinders bonding, and the surface is flat. In order to ensure the strength and adhesion of the self-leveling surface, it is recommended to use M318 water-based interface agent for absorbent base layers; for non-absorbent surface base layers such as stone, terrazzo base, and ceramic tiles, it is recommended to use M320 non-absorbent interface treatment agent for treatment.

Construction method:

1. After the base layer is cleaned, a suitable interface agent should be selected. When the interface agent has been absorbed by the base layer and begins to be in a semi-dry state (about 2-6 hours after the primer construction), start self-leveling construction.

2. Pour 6-6.5 liters of clean water into the mixing container, then slowly add a 25kg bag of self-leveling, stir with a mixer until it becomes a homogeneous slurry without lumps, pour out the mixture, spread it out evenly, and use a special The thickness of the tooth gap scraper is controlled. The newly constructed mixture should be protected from direct sunlight and strong wind, and the mixture must be completed within 20 minutes.

3. Before self-leveling and initial setting, use a defoaming roller to roll the ground to remove the air brought in during mixing. Self-leveling slurries can be delivered using pumps with a delivery capacity of 20-40 liters/min.

Precautions:

Since this product contains cement, it will react with water to produce strong alkali, so avoid contact with skin and eyes. In case of contact, rinse immediately with water; seek medical attention if skin or eyes are injured. After this product is completely hardened, it will not produce substances that have an impact on the body and the environment.

Packaging and Storage:

25kg composite paper bag packaging. This product must be stored indoors, and pay attention to moisture, freezing and sun exposure. No more than 8 layers are stacked on the pallet, and the shelf life is 6 months.

Quote online

Navigator

Contact Hedsom

Contact:Winsom

Mobile:+8618664748006

Email:export@hedsom.com

Comanpy:Hesom SPC flooring

Address:No. 555, Huangpu Avenue East, Tianhe District, Guangzhou, China